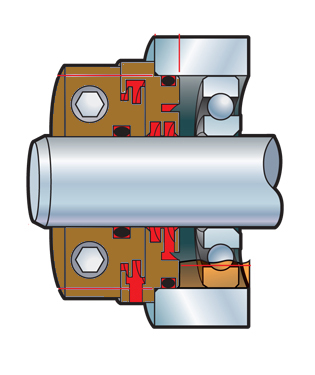

1.686X2.5890X.6325 BEARING ISOLATOR FULL

Read the full article on bearing isolators here. Parker’s ProTech design innovations include the first bearing isolator with a two-piece unitized design, complete wrap around rotor, severe splash oil grooves and a hybrid isolator for flooded applications. , investing in bearing isolators would be a waste of time and money.” Fig -1: Low damping natural rubber bearing1 Fig -2: Elastic design spectrum 2 1.2 The basic equations of motion of the tLinear Theory of Base Isolation This can be explained based on two-mass structural model as shown in Figure 31. If you are not doing everything else right that needs to be done. For these to really work and provide you real-time value, your baselines need to be good. Available in standard sizes from 1- to 6. “Seals are just a small device that helps you improve your reliability program. The Flood-Gard provides the exceptional ingress protection of a bearing isolator, while also creating an ideal running surface for the internal oil seal. Last, but certainly not least, the duo discuss why it’s vital to determine a functioning failure when using a shaft seal because the failure will only occur when the seal is no longer working. It is worth it if you are achieving your goals for the equipment in your facilities.” Determine Functioning Failure It is designed to retain lubrication and exclude aggressive contaminants in non-flooded applications. So, all these efforts are being made to keep the oil clean. Bearing Isolators Parkers bearing isolator selection includes non-contact, labyrinth designs which provide unsurpassed bearing protection for rotary shaft equipment.

You can change it just at the right time before it results in a bearing failure. It helps determine the condition of the oil. “You have to make sure that the samples that you are taking have consistent viscosity and other variables aren’t changing. This is because it directly effects asset health.

1.686X2.5890X.6325 BEARING ISOLATOR FREE

A seal is what keeps the bearing and the oil free from contamination. This is why bearing isolators are used to separate the bearing from its external environment. Machine operating conditions are one major cause of bearing failure. Kovacevic is the long-time host of the Rooted in Reliability podcasts. During the podcast, James Kovacevic, an educator with Erudtio, interviewed the duo.

In a recent Rooted in Reliability podcast, Chris Tindell, SEPCO’s regional business manager, and Woody Nepa, an engineer for product development and reliability solutions for SEPCO, set out to educate listeners on the benefits of bearing isolators. Bearing failure and prevention are hot topics among industry professionals.

0 kommentar(er)

0 kommentar(er)